Knowledge Transfer: The Crucial Stage of Successful Tech Transfer

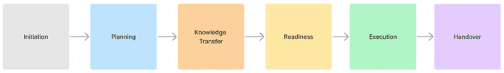

Technology transfer (TT) is a pivotal process in the lifecycle of any product, ensuring the smooth transition of knowledge, systems, and processes from a source unit (SU) to a receiving unit (RU). The Knowledge Transfer (KT) stage, which aligns with both the Planning and Readiness stages, forms a bridge between these phases, fostering effective collaboration and information exchange. Here, we delve into the significance of the KT stage, its key components, and how it ensures the success of the overall tech transfer process.

The Dynamics of Knowledge Transfer

During the KT stage, the cross-functional team involved in the tech transfer process is fully engaged. Key activities that shape the transfer are solidified, even as KT itself continues. This stage is particularly dynamic, as any events affecting the product being transferred demand immediate communication to the TT Project Manager (TT PM).

The foundation laid in earlier stages—such as the TT agreement, quality agreement, TT charter, and project plan—allows the SU and RU to effectively share critical information and technical know-how. The goal is to deliver comprehensive knowledge, data, and experience, enabling the RU to manufacture and deliver the product seamlessly. A collaborative approach during this stage ensures that tacit knowledge, often hidden until challenges arise, is effectively shared.

The Role of Knowledge Management

Proactive knowledge management (KM) plays a pivotal role in enhancing KT. It promotes efficiency between the SU and RU by facilitating the transfer of both explicit (documented) and tacit information. This holistic approach not only aids in preserving and sharing valuable knowledge but also provides insights to refine the control strategy after the transfer concludes. Leveraging KM ensures that the product and process knowledge remain intact and can be further enriched.

Team Collaboration and Communication

The KT stage hinges on a close partnership between team members from various functions such as Business, Technology Transfer Project Management, Process, Analytical, Engineering, Manufacturing, Regulatory, Quality, and Sourcing/Supply Chain. Their collaborative efforts ensure comprehensive knowledge exchange, proper execution of the transfer, and effective resource planning. Regular team meetings during this stage foster knowledge sharing and timely execution of deliverables.

Function-Specific Responsibilities

Business: The Business function focuses on executing the resource plan, removing contractual roadblocks, and fostering a “right-first time” mindset.

Technology Transfer Project Manager: The TT PM facilitates knowledge sharing among SU, RU, and third parties, ensuring timely and complete information exchange.

Process: The Process function shares process performance qualification information, defines the control strategy, and aligns with RU processes.

Analytical: The Analytical function develops method-implementation strategies, identifies opportunities for harmonization, and collaborates on analytical method implementation.

Engineering: The Engineering function assesses facility fit, defines requirements, and manages capital equipment orders.

Manufacturing: The Manufacturing function reviews the master batch record, defines operational documentation, and ensures the RU plant can execute the transfer.

Regulatory: The Regulatory function refines the regulatory strategy, aligns validation approaches, and plans interactions with regulatory authorities.

Quality: The Quality function performs quality risk assessment, finalizes the stability plan, and assesses compliance with various deliverables.

Sourcing/Supply Chain: The Sourcing/Supply Chain function defines the RU bill of materials, considers material storage and handling requirements, and aids in capacity planning.

Stage Gate and Next Steps

The KT stage culminates in a stage gate review where the TT package’s completeness is assessed, risk factors are evaluated, and mitigation strategies are discussed. This ensures that the necessary groundwork for a successful handover is in place. Beyond this stage, the Readiness stage takes over, implementing the prepared resources and setting the stage for the actual product transfer.

The Knowledge Transfer stage is a critical link in the tech transfer process. It bridges planning and readiness, enabling seamless knowledge exchange, collaboration, and resource preparation. With cross-functional cooperation, proactive knowledge management, and comprehensive documentation, the KT stage paves the way for a successful and efficient tech transfer, ensuring products are manufactured consistently and of the highest quality.

Follow CAI’s TT blog series as we step through each of the stages of an effective technology transfer shown below.