During a pharmaceutical technology transfer (TT) project, the Readiness Stage plays a pivotal role by establishing the groundwork for a successful transition. This phase involves meticulous planning, coordination, and execution of key activities across various functions, each contributing to the readiness of the Receiving Unit (RU) for Process Performance Qualification (PPQ).

Overview

The Technology Transfer team delivers the essential components, including documentation, equipment, and analytical methods during this phase. Knowledge shared in the prior project phase, allows the RU to finalize the control strategy, qualify analytical methods, and make necessary facility modifications. Activities in this stage often run parallel to continued Knowledge Transfer (KT), necessitating an iterative process in document development and approval. The risk assessment is treated as a living document, prompting continual review of risk identification and mitigation strategies throughout the TT project. A plant capability assessment is conducted before PPQ, potentially involving preliminary water or engineering runs as part of the overall project plan. The steering committee conducts a stage gate meeting to determine if all requirements are in place for batch execution, providing approval to proceed with the engineering batch.

Key Roles and Activities

Business Function

The RU Business group concentrates on fulfilling all personnel training requirements. It actively oversees the TT team’s progress toward business objectives, including budget adherence, launch date, and projected volume. Engaged with customers for the product transfer, the Business group communicates changes in the business strategy, enabling the TT PM to assess their impact on project assumptions and risk.

Technology Transfer Project Manager

The TT PM takes charge during the Readiness stage, monitoring all workstreams and team members executing plant readiness requirements. Effective execution and coordination of the communication plan are crucial for monitoring progress, addressing challenges, and overcoming obstacles. The TT PM continually evaluates the impact of changes on the TT charter, facilitates decision-making, and actively manages risk. Additionally, the TT PM documents the completion of all validation plans and PPQ requirements in a comprehensive TT protocol.

Process Function

The Process group concentrates on obtaining all necessary data to finalize the product control strategy. Collaborating closely with the Process, Engineering, Analytical, and Manufacturing groups is essential to ensure the deployment of an effective control strategy. Process parameters and ranges are typically classified based on laboratory batches and knowledge gained during clinical development phases. For commercial products, the RU can leverage an existing control strategy in use by the Sending Unit (SU). Process characterization studies at laboratory or pilot manufacturing scale provide insights into the design space and failure edges for product quality and process efficiency. Final engineering batches, demonstrating the control strategy, should be performed before PPQ. The Process group also writes process validation protocols, including the sampling plan and analytical testing strategy, during this stage.

Analytical Function

The RU Analytical group executes the validation plan developed in the Planning stage. All method validation and/or transfer protocols covering various aspects are written, approved, and executed. Compendial methods are performed at the RU to verify suitability. The Analytical group also supports the Process group by analyzing required samples from laboratory- or pilot-scale batches.

Engineering Function

The Engineering group is responsible for installing and qualifying all facility, utility, process, and analytical equipment during the Readiness stage. Collaboration with vendors for Factory Acceptance Tests (FATs) and Site Acceptance Tests (SATs) is crucial to ensure compliance with specifications. Qualification of all new equipment and facility modifications must be complete before proceeding to the Execution stage. Engineering writes and executes qualification protocols, provides training on specific unit operations, and incorporates a preventive maintenance plan and spare parts requirements by the end of the stage.

Manufacturing Function

The Manufacturing group writes the SOPs, work instructions, and batch records required by the RU to execute the process. These documents are used for training personnel and form part of the EHS risk assessment. Manufacturing ensures the plant facilities and equipment are ready for use, supporting the TT Team during Readiness activities and conducting testing to confirm readiness. Documentation and training requirements are finalized before proceeding to the next stage to ensure full readiness for PPQ.

Regulatory Function

The Regulatory group authors and obtains the documents necessary for regulatory submission. Activities include assessing new information, feedback from health authorities, and finalizing product labels. The regulatory strategy is assessed against findings during Readiness activities, including process control, validation strategy, and market strategy. The Regulatory group also collaborates with the Quality group to develop a Pre-Approval Inspection (PAI) readiness plan.

Quality Function

The Quality group collaborates across functions, performing compliance reviews and approving documentation for PPQ preparation. It ensures closure of deviations, CAPAs, and change controls before PPQ. The Quality group develops a procedure for PPQ batch release, collaborates with Regulatory on the PAI readiness plan, and qualifies new vendors and audits material suppliers.

Sourcing/Supply Chain Function

The Sourcing/Supply Chain group orders materials needed for the TT, ensuring setup in the RU systems for timely release by Quality. Aligning equipment and material needs with the overall project plan and established lead times is crucial.

The Road to Successful Technology Transfer

The Readiness stage is a dynamic phase where diverse functions collaborate to establish a robust foundation for subsequent stages, especially PPQ. Each group, from Business to Regulatory and Quality, plays a vital role in preparing the RU for a seamless transition. Successful execution of this stage is not just a prerequisite but a culmination of the planning and collaborative efforts required for a successful pharmaceutical tech transfer.

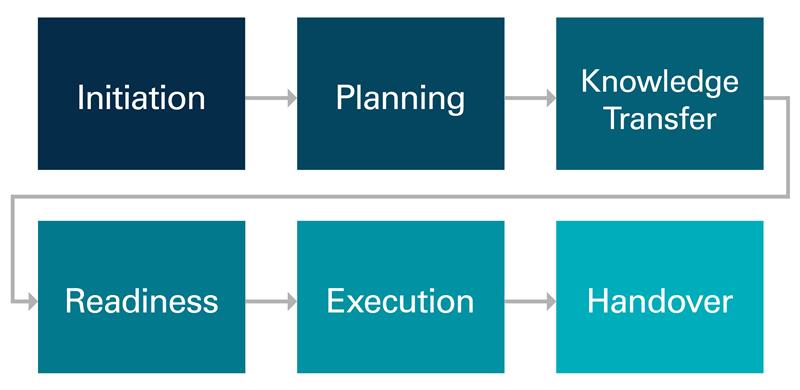

Follow CAI’s Tech Transfer blog series as we step through each of the stages of an effective technology transfer, as shown below.